Volcano Hotends are Obsolete: Just use Nuts!

A Volcano hotend is a variation of the regular V6 hotends where the meltzone is 8.5 mm longer to give 3D printing filament more time to melt for higher flow capabilities. I recently got Pheatus Rapido which is already a high flow hotend. The thing is that they also sell the Rapido in an Ultra High Flow variant, and from the pictures, I found online, I wasn’t really sure how both versions differ. The approach is clever and allows you to switch between High Flow and Ultra High Flow without any hassle. The high-flow Rapido uses standard V6-style nozzles. For the Ultra High Flow, they don’t actually make the heater longer but simply use a Volcano length nozzle and a special nut made from nickel-plated copper to help conduct the heat down the nozzle. This isn’t totally new, and I’ve seen a similar approach used on Slice Engineerings Mosquito Magnum hotend where they increase the length of the meltzone by simply modifying the heatbreak and adding a slab of copper above the hotend.

Pheatus Rapido Ultra High Flow

That’s all great but does this also work on a simple V6 or even Ender hotend? What’s the performance of simply replacing a regular nozzle with a Volcano nozzle and can we replace the custom Volcanizer, yeah, that’s how I call it, by two simple M6 nuts from our toolbox? Oh, and let me tell you that I tested a ton of stuff and different variations!

Pheatus Volcanizer nozzle in V6 hotend

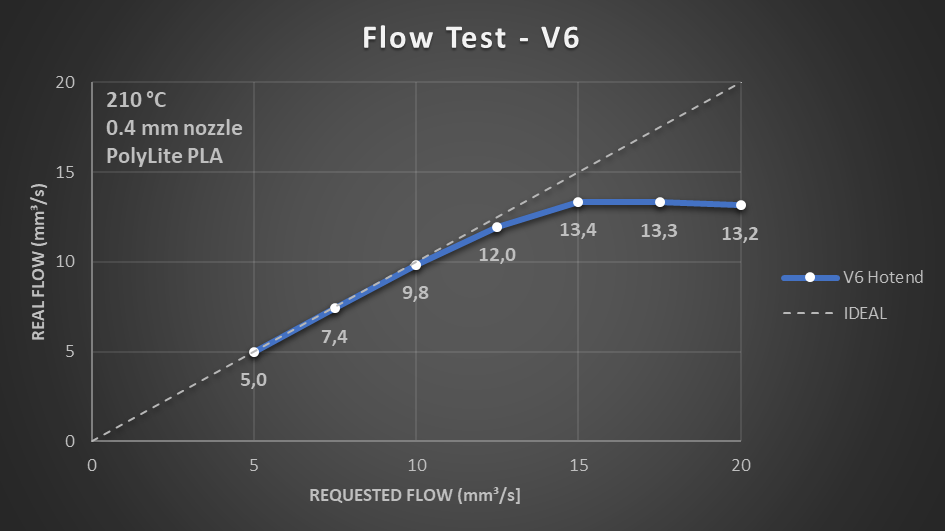

So let’s start with the benchmarks. I did all of the tests using an E3D Hemera extruder equipped with 0.4 mm nozzles and Polylite PLA from Polymaker. I used the same heater and thermistor for all tests to remove them as a variable. Most of the extrusion tests were done at 210 °C hotend temperature, which is what I usually use, but we’ll also look at temperature variation data later. The reason for using a high flow hotend is, in most cases, higher flows to print faster or with bigger nozzles, so I tested the flow capability with simple extrusion tests and validated them later with print tests. Let’s look at a regular V6 nozzle and hotend as a reference. I used Jason's Web flow test generator that he based on my excel sheet to extrude small blobs of material at increasing extrusion speeds automatically.

Finished Flow Test Run

After the test, I put them on a scale to determine their weight. Ideally, all the blobs should have the same weight, but at some point, we feed the material so fast that the hotend is not capable anymore of properly melting it, which creates back pressure and lets the filament grind and skip at the feeder gears. If we put all the measured samples into a graph, we can determine the hotend performance. If the points lay on the diagonal line, the real flow is equal to the requested flow. Any deviation means that we get less than we request and therefore under extrude. A regular V6 starts deviating from the ideal line at a bit more than 10 mm³/s and reaches its limit at around 13 mm³/s.

V6 Flow Performance

Next, I switched the heater block for a genuine Volcano to benchmark the maximum performance we can expect with such a setup. A Volcano hotend is able to increase the melting performance by more than 40% and maxes out at 19 mm³/s. So let’s now get back to a standard heater block and install a Volcano nozzle with the Pheatus nozzle extender I stole from the Rapido. Now take a second and let me know in the comments where you think the performance of this setup will land. For my part, I would expect that it lands somewhere in between the V6 and the Volcano. And here are the results: Using the Volcanizer, I was even able to increase the setup's performance by another 5% and ended up at 20 mm³/s. This seems counter-intuitive, and I still don’t fully understand it, but I got consistently better results in the following tests, as you’ll see in a bit.

V6 vs Full Volcano vs Volcanizer

So let’s take this principle even a step further and test if we even need this custom copper sleeve and start by just installing a bare volcano nozzle into a V6 heater block, which does look kind of strange. But oh boy, even that janky setup delivered the same performance as with a full volcano heater block, and I got up to 19.5 mm³/s!

Volcano nozzle in V6 heater block

But can we increase the performance to the level of the Pheatus Volcanizer by making a DIY sleeve from regular nuts? For that, I purchased brass and copper nuts that I sanded down, so that they are only 8.5 mm high when stacked to cover most of the exposed threads. Similar to the Pheatus Volcanizer, I first screwed them all the way down, then tightened the nozzle against the heatbreak to ensure a good seal, and then tightened the nuts against the heater block for optimal heat transfer into them and into the nozzle itself. The brass nuts performed slightly better than the bare nozzle and landed with 20 mm³/s again above a genuine volcano hotend. Copper was - well not copper. Turns out that I only purchased copper-coated nuts, even though the listing clearly said copper nuts. I don’t know if I got scammed or if I should have known. But maybe even better, because probably almost everyone has simple M6 steel nuts at home instead of copper ones. They performed basically the same as the brass and again simply impressed me.

Flow Test Results

Though I have to say that this test wasn’t super realistic because I didn’t use any cooling, and especially the threads of the bare volcano nozzle might act like an inherent heatsink and reduce the performance, or maybe they don’t. Before we test this, I quickly wanted to talk about how in many cases, the material used for the heater block plays a minor role in the performance of your hotend because the heat transfer to the polymer and the heat conductivity within the filament are the big bottleneck! Even the bare brass nozzle conducts enough heat down its length to melt material efficiently. Of course, there will be a temperature gradient down the nozzle, which will be higher the further away we get from the heat source, but it seems that it’s still not enough, in this case, to impact performance negatively. Also, if you do the maths, the energy required to melt PLA at 20 mm³/s is only around 10 W, which isn’t a lot. So the 40, 50 or even 60W of your heater cartridge are in many cases, easily enough, and the remaining power is reserved to compensate mostly the convectional losses from the block to the air.

Accumulated Extrusion Tests on the table

Speaking of convectional losses. Let’s see how the results of the extrusion tests are when part cooling is turned on, which will also cool part of the nozzle. A normal V6 hotend doesn’t seem to be hugely impacted, and the performance stays basically the same. When using a volcano hotend it’s different due to the higher surface area, and we lose 6% extrusion performance. Interestingly with the Pheatus Volcanizer, the performance drop is only 3%. As expected, the performance drop when using just the longer bare nozzle is higher at almost 9% but still doesn’t render this method useless, but wait what I’ll also try out. The performance drop can be reduced by using regular nuts that add an additional heat transfer path, but the copper-plated steel nuts still drop 6%, though the brass nuts only drop 3% in performance. Again, quite impressive!

Flow Test Results

Though what happens if we insulate the nozzles, which is a standard nowadays with all the silicone socks we have for hotends? On the V6, the performance doesn’t change. The silicone sock on the large Volcano block, though, brings the performance almost back to the one without part cooling. Of course, I didn’t have custom silicone socks for my own DIY Volcanizers, so I just wrapped some Kapton tape around the exposed parts. I highly advice against this method becuase even though Kapton is good until 400°C, the fumes from the adhesive are far away from healthy. This insulation restored the performance of the bare volcano nozzle and made it again perform just as well as a whole Volcano hotend. Similar results also with the steel nuts, though not such a significant improvement.

Flow Test Results

As a final proof that this method works so much better than even I expected I tested two more things. First is the temperature impact. When printing fast, people usually also increase nozzle temperatures to melt the filament more quickly, so I did the same flow tests as before, just at 210, 235, and 260 °C. On the V6 the performance increased by 25% and 50% at the increased temperatures. On the Volcano hotend, we see a similar effect and are able to improve the melting performance by 20 and 30%. And just as before, simply installing a Volcano nozzle into a standard size heater block and adding some brass nuts resulted in almost perfectly the same results as switching the whole hotend. Impressive, and I think I proved my point.

Flow Test Results

Finally, I also did a real printing test, extruding this meandering part at increasing flow rates. The V6 was able to finish 14 mm³/s, and both the real Volcano as well as my DIY Volcanizer were able to go all the way up to 20 mm³/s. Simply amazing!

Printing test: V6 (left) vs Volcano (right)

And because I thought you might be interested, I also threw Bondtechs normal CHT nozzle into the mix where the internal design improves heat transfer and, therefore, significantly improves melting performance. In the regular benchmark, it behaved very similarly to the other high-flow contestants, though interestingly with a different drop-off behavior. In the real printing test, it even slightly outperformed the Volcano and the Volcanizer, still finishing 22 mm³/s until the print failed.

Flow Test Results with Bondtech CHT

So, after all of this testing, is this Volcanizer method a revolution? Well, yes, but also no. I was highly impressed to see how little impact not having a full heater block around the nozzle has and how just some additional metal for heat conduction and heat capacity improves this method even more. But of course, we didn’t really improve the hotend performance over a regular Volcano hotend. The reason why I find this method so interesting and important is because it very quickly allows you to change between a standard flow and a high flow setup. Simply switch the nozzle and the fan shroud plus adjust your z-offset by 8.5 mm and you’re all set! If you don’t want to use simple nuts, Pheatus even sells their nozzle extender separately, and Mellow also recently teased a very interesting nozzle extender. Of course, you’ll get the performance improvement also with a CHT nozzle, but not everyone has one, especially for different diameters and a set of volcano nozzles is super cheap. Regardless of what you end up using, no changing of heater block, thermistor, and heater is required, which can be a hassle, and I have not just only once damaged wires during that procedure. Quickly and conveniently switching is nice because a high-flow hotend also has downsides. If you don’t use its full potential, the longer heater zone will cause more oozing affecting the quality of fine and detailed prints. From an engineering standpoint, performing all of these tests also shows how the thermal performance of a design can be easily tweaked. If the heat conductivity into and within the filament is the bottleneck, everything around is less important for the final performance. And of course, this method doesn’t only allow you to use a volcano nozzle on a standard hotend, but just as with the Pheatus Ultra High Flow setup, you could install even a longer nozzle into your volcano heater block. Just think about the performance of a Volcano heater block with one of our Volcano adapters and Bondtech's new Volcano CHT nozzle! But what are your thoughts on this method? Let me know down in the comments!

The DIY Volcanizer - an alternative to a full Volcano hotend?