Snapmaker 2.0 Review

More info on the Snapmaker 2.0 (Affiliate Link): https://geni.us/oiZdp7

🛒 Accessories for the Snapmaker:

ER11 collets (Affiliate Link): https://geni.us/0Z2Ao4

Carbide Endmills (Affiliate Link): https://geni.us/e0hS

The Snapmaker 2.0 is the second iteration of a modular motion system that can 3D print, laser engrave and cut as well as CNC route by changing the tool head and in it's biggest version comes at a premium price tag of 1800 bucks. Snapmaker reached out to me last fall and asked me if I wanted to take a look at their latest generation machine, which I almost declined! I just thought that such a modular system couldn't really work, because especially 3D printing and CNC routing have very different requirements in terms of movement and rigidity. A 3D printer should be light and fast, whereas a CNC router usually needs strong and very rigid axes. Well, I did some research and didn't find a lot of negative feedback about the machine, so I agreed to have them send me one over. I'd really like to know what you think about those multi-discipline machines. Leave a comment down below!

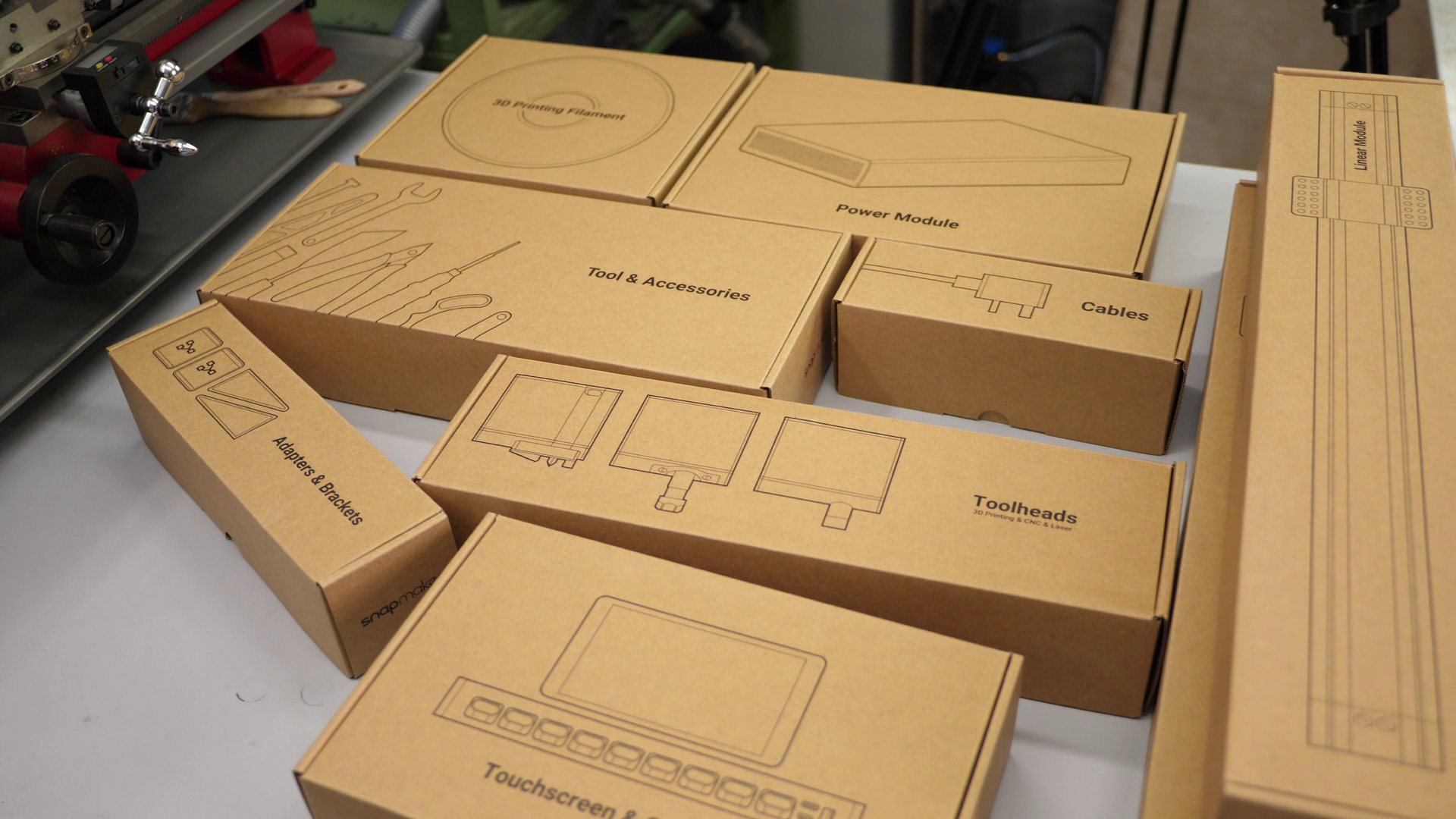

Beautiful packaging of the Snapmaker parts

Well, and when it arrived I really felt sorry for the delivery guy because the package was so heavy that I even had a hard time getting it into my basement. The box itself contained one of the best manuals I've ever received with one of those machines. The rest of the parts were beautifully packed, with custom printed boxes and bags. All the tools necessary were included, even separate safety googles for machining and lasering. Building the Snapmaker was straight forward and took me around an hour, including filming. All the linear motion is performed using the linear modules and they are exactly the same for all axes. You use two for the y and z axis and one across for x. Really well thought out. All the electrical components get routed to the control box that sits on the side using these flat cables with custom connectors so that you can't mix them up. The PSU is a separate box and sits on the side. Lastly, there is a touchscreen controller running Android that sits in a magnetic base and is connected via a flexible cable so that you can nicely control the machine from any angle and offers you the option to tune settings during operation or move the device. Depending on whether you want to 3D print, use the laser or cut stuff with the router, the appropriate tool and platform gets mounted. I started with 3D printing where the tool head is fixed by 4 screws. The heated bed requires 22 individual screws. Maybe a bit overkill.

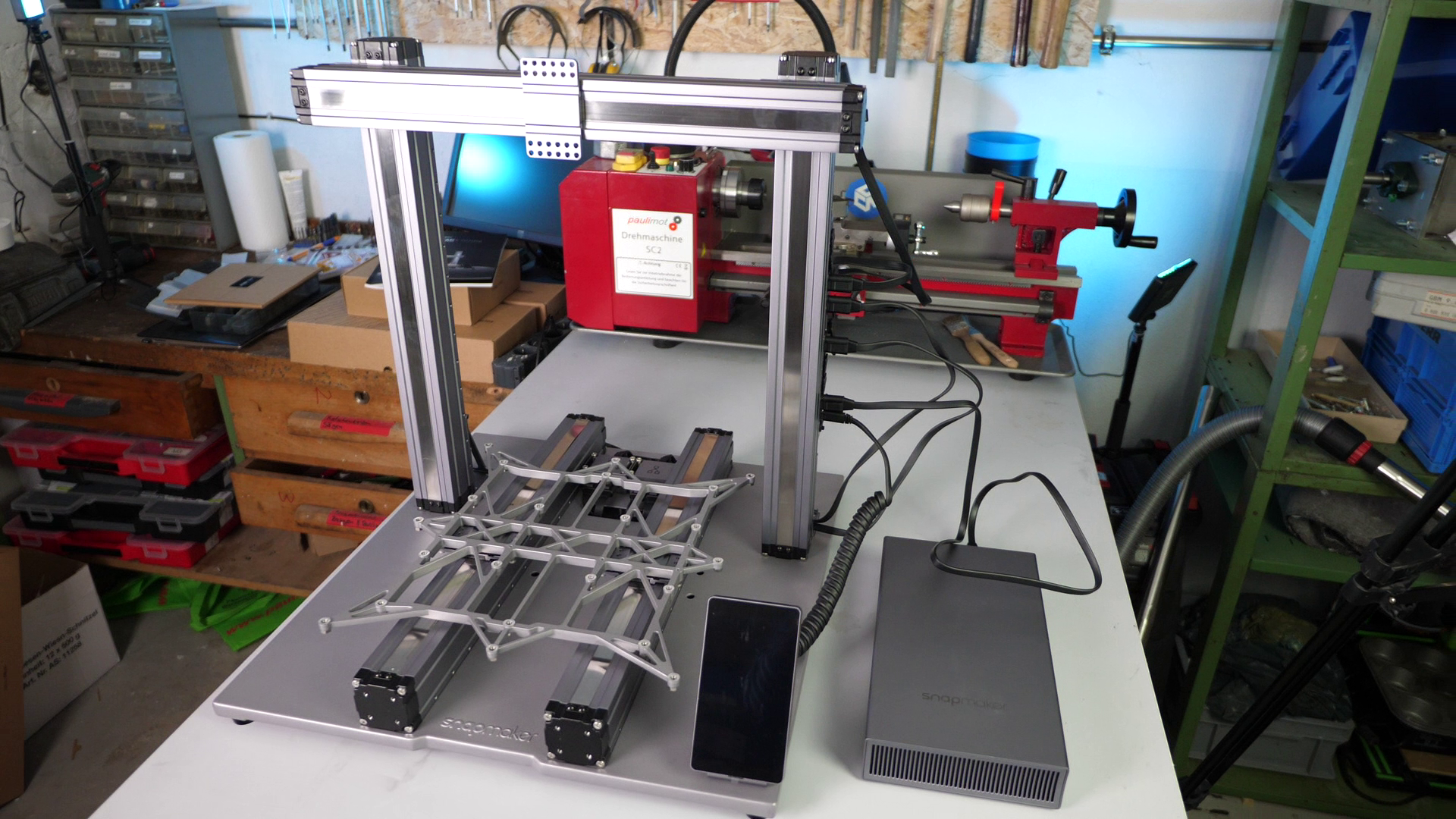

Snapmaker 2.0 with no tool and bed

And here we go. This is the Snapmaker 2.0 A350 in its full glory. This is the biggest version and has a build volume of 320mm by 350mm by 330mm and is therefore the largest machine I currently own. The whole Snapmaker has a footprint without the power supply of half a meter, by half a meter, by 580mm. Besides the A350, there is also the A250 with an around 250mm cubed work area available which is simply a scaled-down version of the A350. The tiniest version is the A150, with 150mm cubed working volume that only has one linear module for the y axis and the x axis is also cantilevered.

The all-metal construction of the Snapmaker

But let's talk about how this machine is built. Well, at first, heavy. Basically everything on the Snapmaker is aluminum. The base and the platform carrier are die-cast; the rest, if we take a close look, is almost all made from aluminum extrusions. Linear module? Extrusion! Tool housings? Extrusion. Angle brackets? Extrusions! Clamps, clamp spacer, controller housing, converter housing, touch screen holder? Everything made from custom aluminum extrusions, with just some minor final machining. That's pretty smart, because aluminum extrusions are cheap at a large scale, enabling them to make almost anything out of nice, metal parts. And moreover, the quality of these parts, at least on the outside, is outstanding. Perfectly machined and anodized and I didn't find anything I could complain about.

A view inside the linear modules

Tool attachment running on steel bars and steel rollers

Let's quickly take a look at the linear modules because this is something I haven't seen on any other machine yet. These linear modules contain a stepper motor, a leadscrew, a linear guide system, and a sled to mount things on. The whole system is more or less well sealed from the outside by those metal strips. A really interesting concept because that means that this is a machine that uses leadscrews for all axis and not like on most other 3D printers nowadays, only for the z- axis. At first, I was a bit concerned about that design decision because even though that makes the axes strong and rigid for machining, a leadscrew usually comes with the downside that it's slower than a belt-driven system and also usually has some kind of backlash, which would be bad, especially for 3D printing. I measured it at around 6 to 7 one-hundereds of a milimeter on the x- axis, after maybe two hundred hours of using it, which is, just out of curiosity an order of magnitude higher than, for example, on a belt-driven Prusa. If that's really an issue is something we'll probably see on our 3D prints. One last thing to talk about is the wiring, which looks kind of clean, but the stiff isolation is quite a pain to route on the underside. But still, all in all, this level of quality and custom parts is something I haven't see on any other machine yet and makes the Snapmaker a machine that's just beautiful to look at.

3D Printing configuration

But after all of this talk, how does the Snapmaker really perform. Let's start with 3D printing. The toolhead features a direct drive extruder with a partly PTFE lined hotend that can do 275°C, a 0.4mm nozzle and part cooling air that comes from both sides. The print bed is a removable spring-steel sheet covered on both sides in a Buildtak-like material. That works so well with PLA that you sometimes rather peel the first layer from the part than cleanly removing it. I, therefore, even started putting some gluestick over it as a release layer. Due to its sheer size, the build plate on the big A350 can only reach 80°C; the A250 though goes to 100°C and the A150 even to 110°C. So printing ABS or Nylon on the biggest model might be a challenge. If those materials are your primary goal, rather consider the smaller models. Heat up times on the big bed are annoyingly long, so it's good that PLA already sticks great to the bed at only 40°C. There is a bed leveling sensor in the toolhead and you can chose in the menu the size of the grid, you think you need.

Print quality - sliced in Luban

Part quality on my first prints wasn't really great due to the slicer and I at that point thought it was a must to use PrusaSlicer or similar. That improved quite a bit with the latest software and the print results now are really nice. The printer is not crazy fast due to the leadscrews it uses for all axes, but if you're not in a hurry, that's not a huge problem. The backlash I've measured in the beginning doesn't seem to be a problem because surfaces turn out nice and smooth. Overall the results are way better than expected and totally usable. Though one point I didn't talk about yet is the printing noise, and this is in my opinion one of the worst things about the Snapmaker. Not only does the power supply have a permanent-on fan and sound like a jet that's starting, but since they are not using silent stepper motor drivers, you just can't have this machine anywhere close to where you're working. It's really annoying and when it's running, I can hear it through our whole house. Snapmaker, why did you do that on such a premium machine?

Laser configuration

But let's continue with the laser module. The toolhead includes a 1600mW 450nm blue diode laser as well as a camera. From my experience with other blue lasers, I can say that these are probably real 1600mW because my 2500mW and even the, on the label 5500mW don't do nearly a similarly good job while cutting or engraving. When you installed the module and the aluminum grid table, it first takes you through a calibration procedure in which the camera itself and the focus position are mostly automatically calibrated. The camera calibration is important because that gives you the possibility to automatically map the working area and then place your designs directly in software at the perfect positions. Of course, with this amount of laser power, you can't expect too much, but I was pleasantly surprised to reliably cut 4mm soft plywood in 4 passes at 140mm/s.

Engraved and cut 4mm plywood

Thick cardboard is cut in two passes and thinner one even easily in 1 pass, not even to speak of paper. Even though there is no real air assist, they at least blow some air through the laser nozzle to keep the smoke away and help it do its job. Keep in mind that you can't cut or engrave any transparent materials like glass or acrylic with such a blue laser. Engraving also works great on wood, leather, and fabric.

Laser-etched anodized aluminum

Even though you can't engrave raw metal, you can laser etch anodized or pained aluminum and other metals, which could be a valuable application. Though there is one big caveat with such laser systems, and that is safety. This is a class 4 laser that can easily blind you if you're not careful. Of course, there are safety googles included that seem to do a good job, but it's just not as safe as with a complete enclosure around that should even have a safety switch on the door. Snapmaker sells an addon enclosure, but that will set you back another 600 bucks! And then there are the fumes. The Snapmaker obviously doesn't have an exhaust, so all the smoke and fumes will build up in your shop which is potentially harmful, especially if you work with plywood that uses nasty binders or you laser plastics. So just keep that in mind, really think about optical safety, and only work in an open, well-ventilated area. This is no kids toy!

CNC machining configuration

Let's finally talk about CNC machining which is the discipline I was most worried about, just because the requirements of 3D printing and machining are quite different. The machining tool head features a spindle that can go between 6 and 12 thousand rpm and has a tiny 50W of power. The bits are mounted in an ER11 collet. The one included is 1/8", which is a pretty standard size and will also fit many of your Dremel tools you might already have. The working surface for machining is a piece of MDF with a bunch of drive-in nuts that you can use with the included clamps. I use screws to directly fix bigger workpieces to the table. In the end, it's a wasteboard you're working on. The thing I'm really missing though, is a big emergency stop button and I would already be happy if that's only on the control screen. In CNC machining, things can go wrong fast, and an emergency stop button could potentially save your tool, your part or the Snapmaker itself. Snapmaker teased this as a future addon, together with a rotary table, but it's unfortunately not available yet. The first piece I machined was just a round sign for a friend with two holes for a bit of string. Since I needed two, I prepared one Gcode in LUBAN and the second in Fusion360, which both worked well. I used 0.5mm stepdown at 1000mm/min with a 3mm, single flute endmill, which is already the limit of the spindle and you sometimes even hear it slowing down. Don't expect a lot but I think it's very acceptable for small machining projects.

Multi-tool 3D machining

I tried some muti tool 3D machining using Fusion 360 and carved a half-sphere hole into some pinewood. The first operation roughly cleaned out the material with a flat end endmill. Then I switched to a ball endmill, adjusted the z-height and cleaned up the hole in a spiral contour. Very pretty results, to be honest. I'm really impressed.

Machining aluminum

I thought it was a stupid idea, but still wanted find out what happens if I try to machine aluminum. So I mounted some 4mm scrap aluminum sheet and tried to machine a circle at a conservative 250mm/min and 0.3mm stepdown. I was prepared to sacrifice the endmill, but man, that didn't happen. There was a lot of chatter, but the Snapmaker was able to machine the circle. Still no Haas CNC mill but if you have time and need some small aluminum bracket, this seems definitely doable! Since the table is not very rigid, always try to machine in the center. The only thing that still concerns me a little is the dust ingress into the Linear Modules. They are protected with the metal strips, though not hermetically sealed. So in order to get as little dust as possible into those, try using a vacuum as much as you can. One thing I also need to add right here is that the Linear Modules don't seem to handle cold temperatures very well. I only had around 13°C in my basement during the winter, which caused lost steps during fast travel moves. Up in my nice and warm office, that wasn't a problem I ever encountered.

Snapmaker Luban

This was the Snapmaker in operation, but we haven’t taken a look at the software yet, that’s used to generate the GCode for the machine even though I already mentioned it a couple of times. Snapmaker ship their own software called LUBAN with the machine, that's even open source and is an integrated preparation software for 3D printing, laser operation and CNC machining. This tool is one of the strengths but also one of the weaknesses of the Snapmaker. It has the same look and feel for all three disciplines, which is pretty nice for beginners. In the 3D printing environment, you can load your stls and have a pretty limited set of options to play around with. It comes with presets for different materials and quality settings that work allright. In the Laser environment, you can either directly create simple shapes and text or load vector files as well as raster images. All of the necessary settings are there to change the order of operation, speed, laser power, and number of passes. One thing that is really important for cutting material is that you can adjust by what amount the z-axis shall be moved after each pass so that the laser's focus is always where it needs to be. One huge advantage of such a machine in comparison to the usual laser engraves you find from different vendors. Next, we get to the CNC machining environment, where we can already get an idea about the state of the software because it already gives us a warning, that this currently an alpha feature. To be honest, that sounds worse as it really is because most of the settings and operations for basic machining are there. You can again either create simple shapes or load vector or raster files and apply different settings, like pass depth, speed, etcetera, and even have the option to add tabs to that the part you're making so that it is still held in place after the machining operation. The generated Gcode can then either be sent and started directly via WiFi or put on a USB stick and loaded onto the machine. I preferred to use the latter because the wireless connection is not always that stable and every time you want to connect to the machine, you need to confirm that on the screen, which is a huge pain if your PC you prepare the data on is not in the same room.

CAM for the Snapmaker in Fusion 360

All in all, the software works but definitely has some issues in different places. Moving and orientate objects is hard and clunky. It's not always super stable and sometimes just does things that are wired. Parameters are limited, but I think that's also a bit by design to help you start creating parts fast and not overwhelm beginners. There has also been quite some development over the last months in which I've tested it, which constantly improved the experience. The great thing is that if you are an enthusiast in any of the disciplines, Snapmaker doesn't hold you back from using your own tools. The Snapmaker 2.0 runs Marlin firmware, so you can easily create your 3D printing GCode in PrusaSlicer or Cura with even better results in the end. There are guides to setup the Snapmaker for Lightburn to improve your laser capabilities and they even provide a postprocessor with a guide for Fusion360 so you can even do the most fancy 3D machining operations. Kudos for that!

So that's basically it. Can I recommend the Snapmaker 2.0 for its 1800 bucks? Well, I'm totally honest here: If you are primarily looking for a 3D printer, buy a dedicated 3D printer. If you're looking only for a laser cutter, buy a CO2 laser. If you only want to CNC machine, buy a CNC router or print yourself a MPCNC. You’ll probably get better results and all of them alone or maybe even combined will set you back less or just as much as the Snapmaker. Though, if you want to do a bit of all those disciplines, don't want to learn three different software tools right away and maybe don't have a huge workshop, then I think you'll hardly find something better in that price range than the Snapmaker. If I wouldn't have all of this equipment, I would be totally happy with such machine in the workshop. Well and you should definitely have a workshop, because due to its noise level it's noting for an office space.

I was really doubtful about this machine in the beginning, but I was proven wrong. It's not the best 3D printer or laser cutter or CNC router, but everything it does is better than just okay. Build quality is outstanding and the software, even though not perfect, is good enough to get you going and if you want to do something fancy, the Snapmaker is open and can be fed with GCode from other software! Also, there is a quite active community around the machine that has already developed a bunch of upgrades and will try to help you if you're stuck somewhere. Full disclosure, as I said in the beginning, Snapmaker provided the A350 for free, still everything in here is my own opinion. If you want to have more information, you can find links to the machine and suitable accessories in the description.

PrusaSlicer profile (not perfect but it works): DOWNLOAD

More info on the Snapmaker 2.0 (Affiliate Link): https://geni.us/oiZdp7

🛒 Accessories for the Snapmaker:

ER11 collets (Affiliate Link): https://geni.us/0Z2Ao4

Carbide Endmills (Affiliate Link): https://geni.us/e0hS