Impressive 3D Printing Technology at FORMNEXT 2022

Recycling Fabrik

Let’s start with something awesome and this was the booth of the StartUp RecyclingFarik, which is German for Recycling Factory and they basically are the only company worldwide to which you can send your 3D printing waste, and they will turn it into new filament. With RecyclingFarik, if you live in Germany they will send you a free shipping label if you collected at least 2 kg of PLA and PETG or 7 kg of material if you live in Europe.

Recycled Filaments and Prints

Once they receive your package they’ll sort the material, by type, color and potentially remove unwanted stuff. You’ll be receiving reward points depending on the quality and quantity of material you provided that you can use to purchase recycled filament from their shop. They have to process large quantities of material to be economical, so you won’t be receiving filament from exactly your sent-in material but it might be part of the amazing gradient colors that they make. I was highly impressed with what they are able to achieve and they told me that the quality of their material is very comparable to one made from virgin material, and they only see a small degradation in mechanical properties.

Fraunhofer IAPT

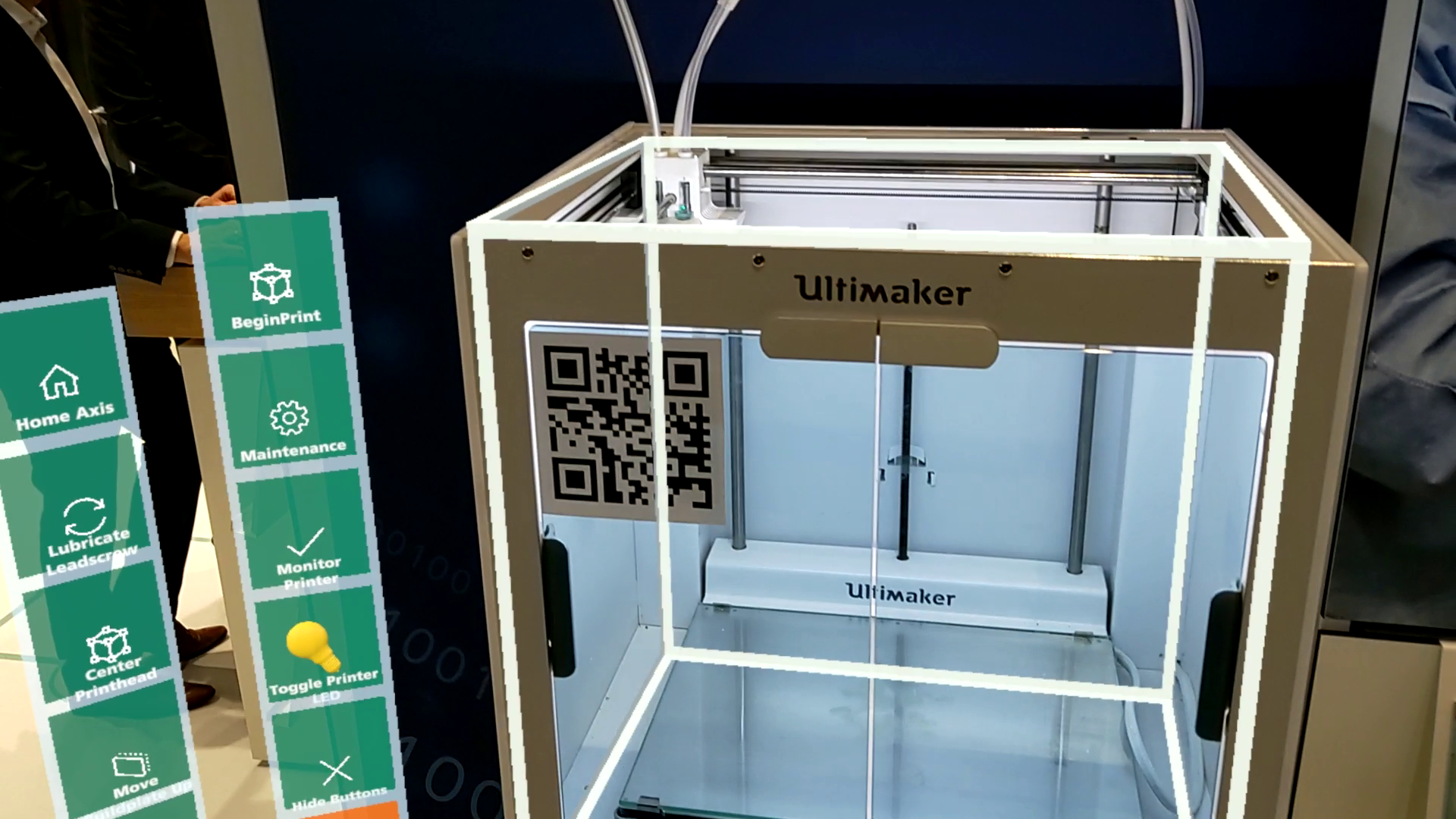

Next I visited the Fraunhofer IAPT, which presented an impressive new way to interact with a 3D printer. They developed a mixed-reality demonstrator to control and maintain your printer which could make additive manufacturing, especially for tech un-savy people, more approachable. I never wore a Microsoft HoloLense before and was blown away once the demo started.

View Through the AR Goggles

The mixed-reality headset projected a set of virtual controls into my view that allowed me to browse through prints, take a look at them and then just drop them on the printbed to start. Everything was controlled via hand tracking and was super intuitive. Yet starting a print is usually not the hard part so the feature that instead caught my attention was interactive maintenance. If you need to for example grease the leadscrew, their system guides you step by step through the process, highlighting where you need to work, which reduces the risk of misinterpreting a manual and just streamlines the process. Fraunhofer is a research organization active in a ton of different fields to develop the technology of the future and this was a great demonstration of how they imagine how users could work with and on machines tomorrow!

MaCh3D

industrio.co/en/portfolio/mach3d

If you’ve been following my channel for longer, you’ll know why I was excited to see the booth of MaCh3D. They showed off a tabletop tensile and compression tester with the goal of getting material testing directly onto the shop floor and out of laboratories because they say it will be easier to use and will only cost around ⅕ of the price that competitors charge. The tester that they showed is capable of applying 5 kN, which is around 500 kg or 1100 lbs of force onto different samples ranging from dogbone specimens to even adhesion tests.

Table Top Tensile Tester

The base model measures only strain and displacement but you can add external extensometers or strain gauges and they are even currently validating an AI model to accurately predict strains from their displacement measurements. Maybe I can convince my wife that this would make an awesome birthday present.

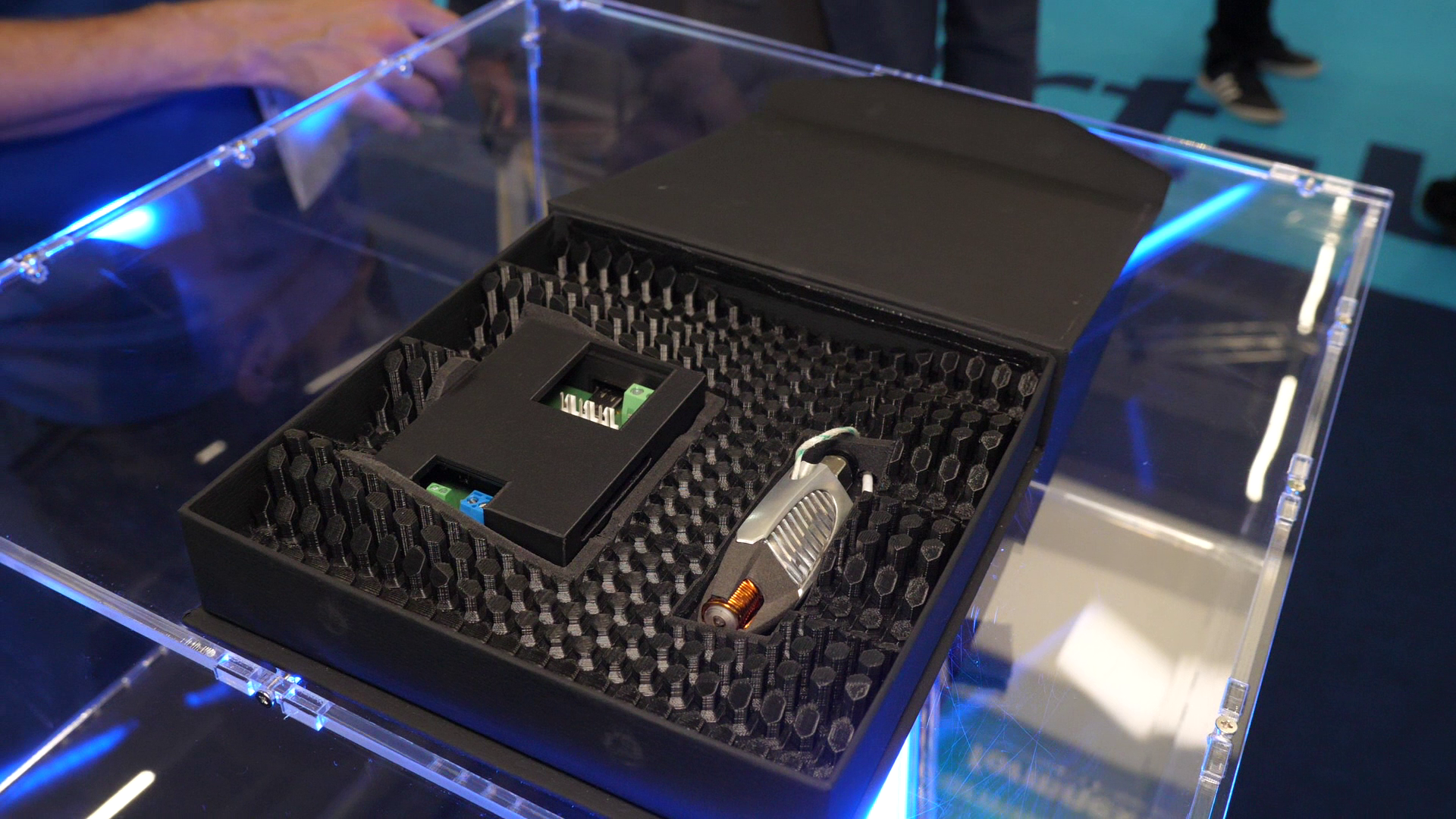

PLASMICS

Next, I saw some really innovative 3D printing technology at the booth from the Austrian company Plasmics. Their INo Trident hotend features an induction nozzle. They have a special hardened-steel nozzle core and a copper coil around it. Custom electronics that interfaces with your mainboard control the high-frequency magnetic field, which then induces eddy currents in the nozzle core and heats it. This doesn’t only result in impressively fast heating, which means 5 seconds to 200 °C and 15 seconds to 400 °C, due it the low thermal mass also letting you cool it down in an instant and allowing for very precise and responsive temperature control.

PLASMICS INo Trident Hotend and Custom Electronics

The great thing here is that the heat is generated very close to where it needs to melt the filament, so temperature gradients are reduced and melt rates increased. The responsiveness of the hotend will also allow better gradient prints because you could even vary the extrusion temperature within one layer and create different densities with, for example, Colorfabbs series of foaming filament, where the material density is adjusted by the print temperature. Plasmics successfully launched the INo Trident as a Kickstarter last year and I hope it becomes available for purchase and for me to test, soon!

QBig

1.7m x 1 m x 1m Large Volume Printer

But let’s come from a hotend and nozzle that you can put into your own machine at home to more industrial solutions and start with QBigs Large Volume Printer that uses a variable diameter nozzle. Their machine, with a build volume of 1.7 m x 1 m x 1 m uses a nozzle diameter of 1.5 mm for the contours, and every three layers, it prints the infill at a nozzle size of 3 mm.

Variable Size Nozzle

And they are not switching physical nozzles or even have separate printheads but developed a nozzle that can dynamically vary its orifice diameter. This way, they are able to print huge parts with details surfaces yet don’t waste a ton of time on the infill, because it’s printed very coarsely. All of this runs with a pellet extruder so they don’t need expensive filament for their big parts and it was really interesting to talk with them about a g-code postprocessor they developed that allows to very accurately adjust the flow of the screw extruder to even use very clean retracts and not ooze a ton of material between the travel moves which allowed them to be one of the few companies not only showing vase mode prints on large volume printers. I couldn’t find any detailed information on how they control the nozzle diameter, and unfortunately or fortunately even didn’t find a patent that explained the mechanism.

Sculpman

Yet the next booth that I visited very clearly showed how they vary their nozzle diameter. This is Sculpmans ribbon nozzle. A nozzle that is not round but rather a slot that can be dynamically controlled, improving print speeds but still allowing for small details because it can basically merge individual circular extrusions into one very wide one but still can be small for details.

Ribbon Nozzle

Since the nozzle orifice is not symmetrical, they need an additional rotation axis, that rotates the whole hotend assembly so that it aligns with the printing direction. Doing the path planning for the orifice and rotation axis is, of course, not something you find in a regular slicer, so they are working on their own software suite and since they mainly showed vase-mode parts, software and probably also complex models with retractions might still be a challenge.

LIQTRA

Another really clever and nice to-look-at way to improve the productivity of an FDM printer was showcased at the booth of LIQTRA. Their FX-7 printhead has seven individual nozzles next to each other that can extrude material simultaneously. So when they are printing a circle, for example, the individual nozzles dynamically switch on and off, depending on where they currently are at the part. They printed some parts with different colored filaments for each nozzle, which nicely illustrates the transition between the individual nozzles.

Perimeter printed in one go with several nozzles acitve at a time

The advantage of this system, compared to one single, big nozzle, is that this allows them, with clever path planning, to still be able to reproduce fine details like with a single nozzle printer but extrude the rest of the part with very wide extrusions. Depending on the type and size of the part you print, you can choose a different nozzle plate with individual orifice sizes and spacing. They claim a 300% increase in productivity with their system. This toolhead only works because they developed a slicer that can do the complex planning for each of the seven nozzles, which shows how important the connection of hardware and software is, to achieve the most in a process.

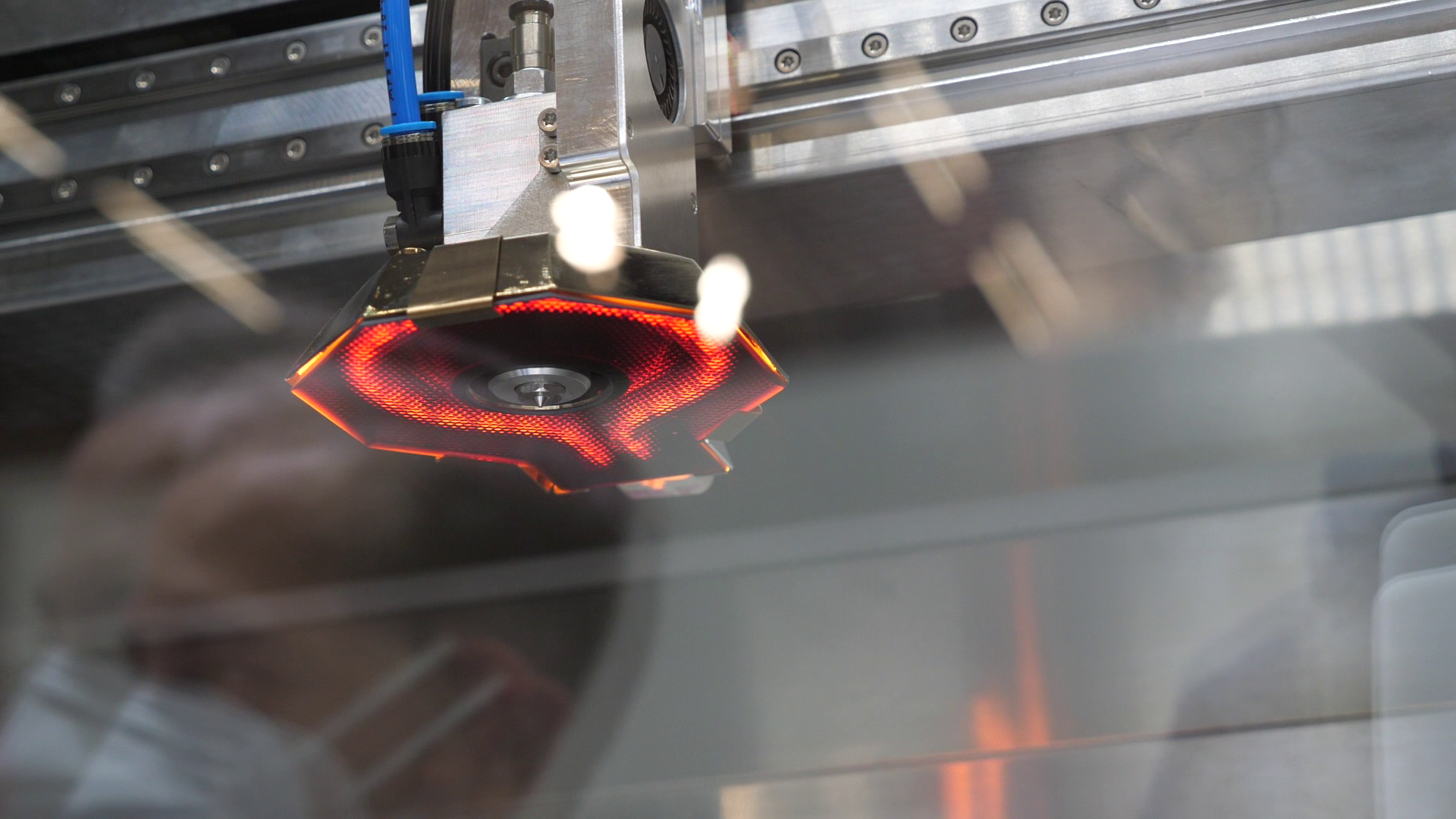

APIUM

Apium, who build 3D printers for high-tech polymers like PEEK, demonstrated something very similar. These are layer adhesion samples printed vertically out of PEEK. At Formnext, you could use a center punch at their booth and try to delaminate the layers.

Layer Adhesion Samples

Yet they found a way to print these samples with almost perfect layer adhesion because instead of splitting apart, the center punch just squished the material. One of the ways they achieved these impressive properties is by using a ring heater around the nozzle, which heats up and even partially melts the existing print before a new layer is printed on top. Yet they don’t simply run the heater all of the time but use a clever algorithm that calculates how much a specific part of the print go already heated and tune the power of the lamp accordingly.

APIUM Infrared Heater

This prevents parts of a model from getting too hot, while other regions remaining too cold, and ensures very consistent temperatures of the upmost layer before the nozzle extrudes a new one. And with this system, they even don’t need a fully heated chamber which otherwise is a necessity for these demanding polymers.