ColorFabb LW-PLA - Testing Foaming PLA

A couple of months ago Colorfabb released two really interesting new Filaments that are called VarioShore TPU and LW or Lightweight PLA. The cool thing about those materials is that, on the roll, they look like any other regular filament but during printing you can adjust their density by changing the nozzle temperature. The heat causes the generation gas withing the filament that then foams up with microscopic bubbles. With the TPU you notice that it gets softer when printed at higher temperatures hence, varioshore TPU, the PLA really nicely foams up and gets that matt surface. If you’re hearing foaming now you might wonder why this is a good thing because we usually avoid that effect by drying our filaments. In this case though foaming is used in a way more controlled manner that causes the extruded filament to foam up very uniformly with tiny bubbles. This isn’t achieved with water, like it is the problem with bad filament but by adding a blowing agent. A blowing agent is a substance that creates a gas when heated and is therefore capable of creating a cellular structure in our polymer. This can even be baking soda or some other chemicals that are finely mixed into the material before the filament is extruded. You don’t end up with a foamy filament during extrusion because it’s extruded under the decomposition point but the higher temperatures in your nozzle later start the process.

This isn’t something totally new and quite common in normal industry for making a variety of foam parts. Some agents are even called “yoga mat” chemicals for being the foaming compounds used in the making of these soft pads. I haven’t seen much of this technique being used in 3D printing but I know that there is at least one other 3D printing filament that has been using a similar method for a while. Polymakers Polywood doesn’t contain real wood like other wood filaments but also uses foaming to get a similar texture without the danger of clogging or destroying the nozzle. Colorfabb are now marketing comparable products for the use in mechanical applications rather than only esthetic ones.

3DJake and Colorfabb themselves provided a couple of rolls of their foaming materials for me to play around with. I was especially interested in the Light Weight PLA and this video will cover the use and performance of that material. If you’re also interested in the VarioShore TPU, let me know in the comments. As I recently have shown again, PLA is still one of the strongest materials but is quite heavy with a density of around 1.3 g/cm³. So, for light-weight designs it’s sometimes challenging to use it. The 3D printed plane that I did a while ago is really beautiful but has the problem, that it’s quite heavy. Even though most of the structures are just single walls, some structures might not need as much strength and stiffness, like the hull for example, though you’re limited by the diameter of the nozzle. The light weight PLA claims that it can foam up to almost 3 times its volume, effectively reducing the density to a third. But is the material still mechanically usable in it’s foamed up state or does that process severely degenerate the performance?

Foamed up filament

In order to find that out, I’ve first tuned in the material for different temperatures and then printed and tested a ton of samples to analyze its performance. And before someone asks, I even annealed the foamed parts to see how they fair!

LW-PLA Temperature Test Tower

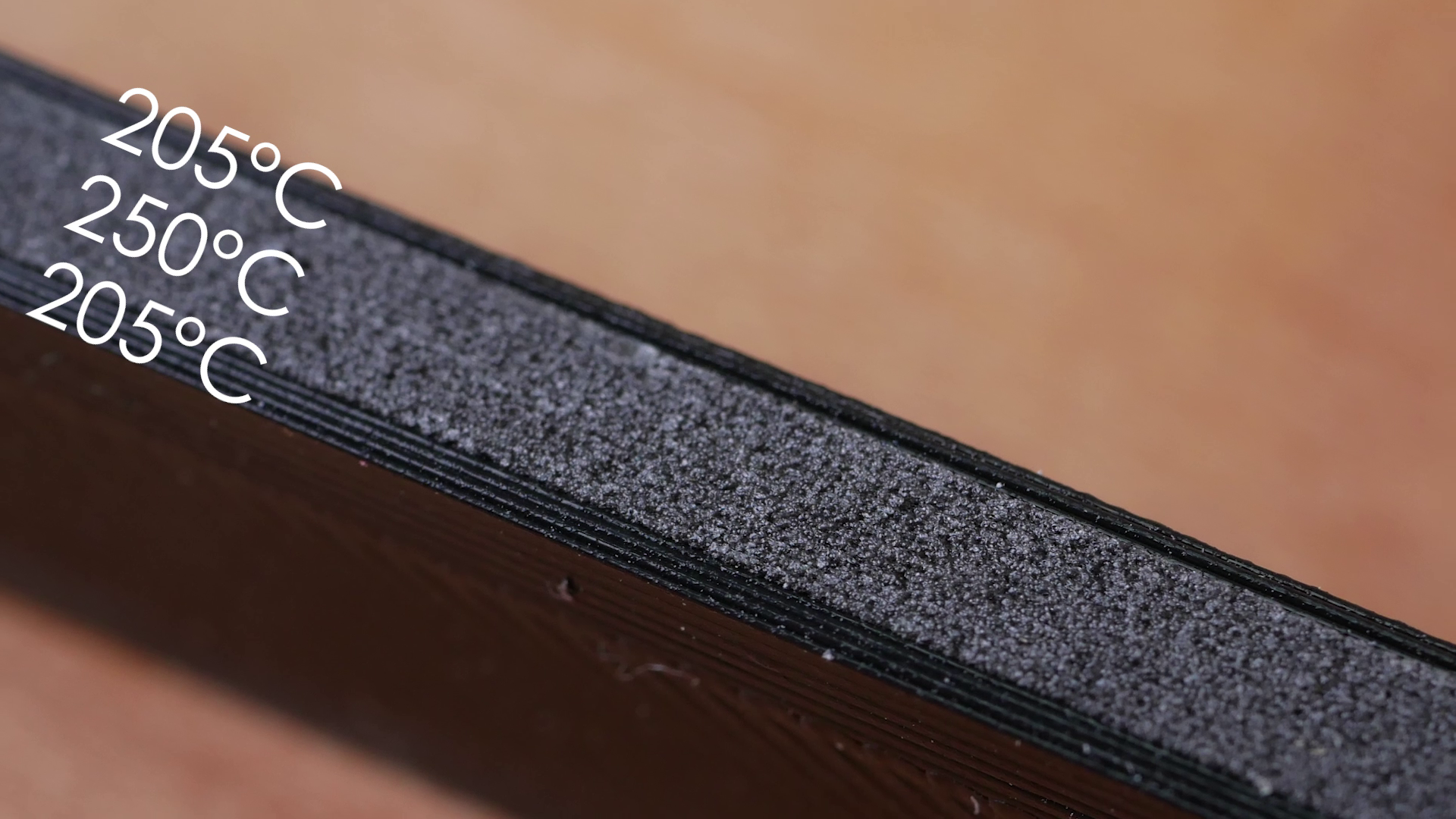

In order to tune the parameters, I took guidance from the Colorfabb website (https://learn.colorfabb.com/lw-pla/) but also a great blogpost that Richard Horne posted (https://richrap.blogspot.com/). Link’s to those resources are in the description and really worth reading. In order to see how the material generally performs I printed a simple single wall test part on which I first varied the nozzle temperature in 5°C steps and later in 10°C steps starting from 200°C to 280°C. All the way up to 210°C the material looks like regular PLA. At 215°C you start noticing small bubbles on the surface that seem to get more and more up to 250°C at which point it looks fully bubbled up. First impression handling it is already really nice since even the part printed at 280°C still looks very flexible. When the material starts bubbling up you need to reduce the extrusion amount because the volume increases and you’d otherwise over-extrude. To tune the extrusion amount I printed sets of more single walls part where I measured the wall thickness to determine the reduction in extrusion amount. You need to do that a couple of times, because the degree of foaming is not only a function of temperature but also printing speed, material flow and so on. The difference in density and stiffness can even be heard if you pluck the printed parts. In the end I produced a nice graph that shows that at around 215°C the foaming starts and at around 240°C or 250°C you reach the maximum. This is basically the range in which you can play to adjust density. I didn’t reach 3x the volume but more than 2 was possible which is a reduction to around 44% the density of regular PLA.

Flow correction for different temperatures

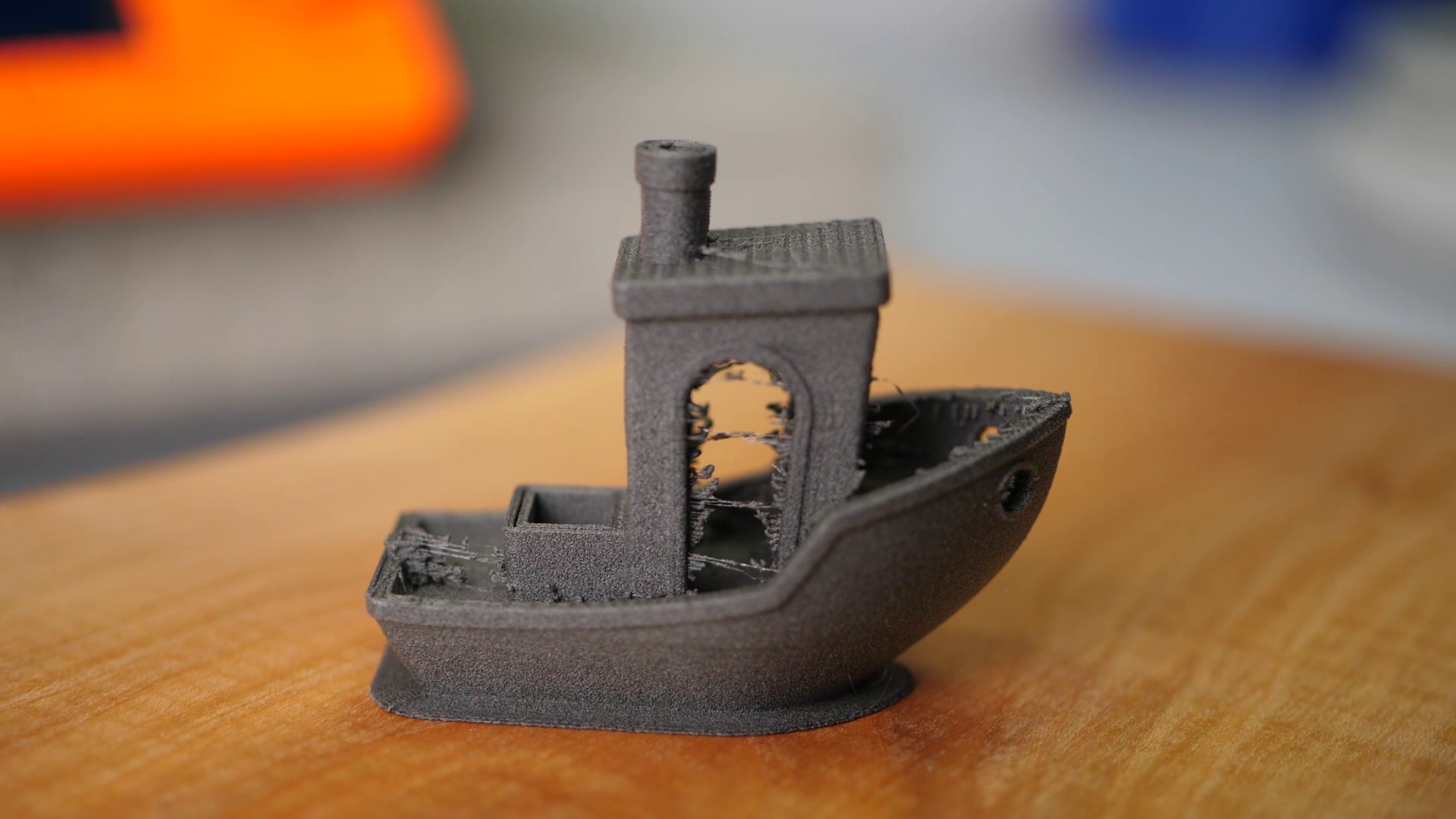

With these flow settings I printed a couple of test parts where I already noticed that due to the foaming-nature you’ll get quite a lot of stinging on your parts if you have travel moves within you parts. The material is fairly easy to remove though. You should increase the retraction amount but if you select it too high, you’ll clog your nozzle. For my original Prusa i3 Mk3s the maximum possible was around 2.5mm. Anything more caused problems. This material requires some tuning for your application but in the end, you can get really nice looking, matte parts out of it that are quite a bit lighter than they look.

3DBenchy printed in LW-PLA

So, let’s get to the mechanical tests. If you by the way want to take a second look at the result graphs you can check my website and if you want to get access to the full test report, consider becoming a Patron. Regardless of that, make sure that you’re subscribed to the channel and have selected the bell to not miss any upcoming videos.

I’ve tested the mechanical properties of Colorfabbs LW-PLA at 3 different temperatures: 205°C for the un-foamed material, 225°C which is 67% density and 250°C which results in 44% density. Additionally, since people seem to be interested, I also annealed one set of the 250°C parts to see if that changes properties. For each temperature I printed a set of dogbone samples for tensile strength and layer adhesion as well as one of my test-hooks for a more realistic loading scenario. Then I printed impact test samples and a bar with which I test the bending stiffness. I checked the weight of the specimens on a scale and verified that the weight is really proportional to the flow rate and it was.

Let’s start with the tensile tests. The samples printed horizontally are simply clamped in my DIY universal test machine and then loaded at a constant speed until they failed. Our baseline part without active foaming failed on average at 49MPa which is a little low for PLA but on the other hand the material yielded quite a bit before if failed and behaved much like a Tough PLA or a PLA+. The foamed parts at 225°C were able to bear roughly half of the load and failed on average at 24MPa which is, considering the density of 67%, a little bit low. So, the strength and density don’t seem to be totally proportional but I think, the values are still pretty good. This is a quite well known phenomenon of cellular structures and for example described in the Gibson-Ashby scaling law, if you want to do further reading on this topic. This scaling law gives you the relation between density and property and is usually not linear. The degree of un-linearity is dependent on the type of lattice or porosity you have and differs in severity. The parts printed at 250°C were able to bear a quarter of the reference and snapped at only 12MPa but not in a brittle way and they seemed to yield considerably before failure.

Tensile Test Results

The layer adhesion samples look a little differently for better printability and were also tested on the Universal Test Machine. The parts without foaming snapped at an impressive 2/3 of the strength of the horizontal specimen, the 67% dense parts were able to bear 13MPA and the lightest parts failed on average at 4.3MPa. It seems that the higher we go with the temperature and the more foam we produce the more of a knock-down we need to take into consideration with our designs. Due to the flexibility and toughness of the foamed parts I still think it’s greatly usable if applied properly.

Tensile Strength Scaling Law

The hook test showed comparable results to the dogbone samples. The hook printed at 205°C snapped at 59kg, the next one at 30kg and the lightest at 17kg. I also put 3 of the hooks into my convection oven at 100°C for 1h to anneal the material. The first thing we notice is that the standing hooks are very deformed because PLA grows quite a bit in z-direction during that process. The lying part was only a little smaller and a bit thicker. The tests unfortunately showed again what I also already investigated in the past, that the properties aren’t largely altered and the horizontal as well as the vertical hook failed at very similar load levels than the untreated ones.

Hook Test Results

Before we get to the impact test, let’s take a look at the stiffness of the foaming PLA that I tested using a 3-point-bending test. This might be a property that is important for you if you are designing your plane for example, so that the wings don’t flex too much. The parts are placed in the jig and then loaded successively with weight while the deformation is recorded. The results are quite similar to the strength tests, meaning that the knock-down in stiffness is higher than the decrease in weight. The dense part had a modulus of 3200MPa, the 67% dense part a value of 1600MPa and the part printed at 250°C only had a modulus of 900MPa. With the last one I even wasn’t able to add all 4 weights, because when I added the 3rd one, the material already started to slightly give.

Bending Modulus of LW-PLA

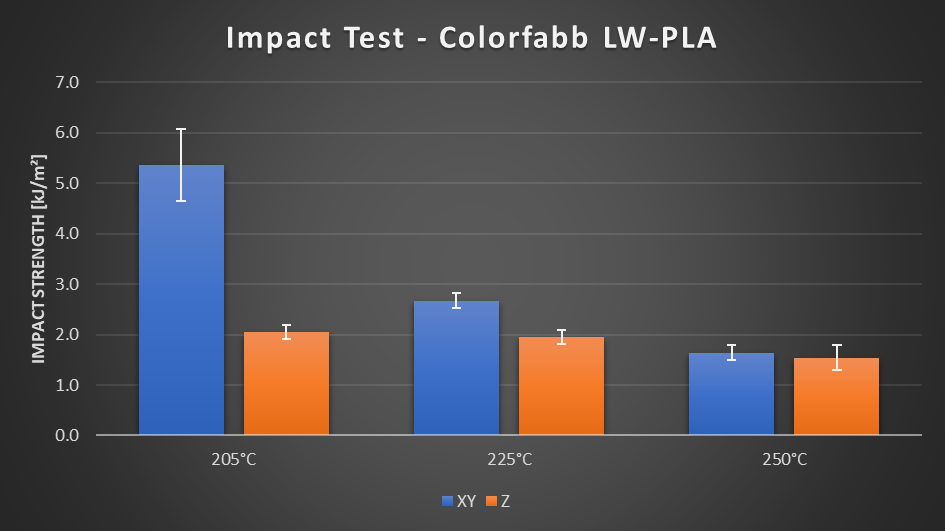

For the last test I’ve analyzed the impact strength of the material, so the ability to absorb energy during a quick impact event. If a material is brittle and shatters, the energy absorption potential is small, if a material yields before breaking, even at these high impact speed it is more tough. The specimens are put into a vice and then hit by a hammer. The horizontal specimens again behaved similarly to the static tests, though the base impact strength was higher than regular PLA and more like a tough PLA. The standing specimens behaved differently, because they all were able to absorb quite a similar amount of energy which is great because that means, that your parts, even at higher degrees of foaming will be able to take some impact.

Impact Test Results

All in all my tests showed me that the unique property of Colorfabbs LW-PLA seems to be something that could allow really great designs if applied properly. The mechanical properties will suffer with higher degrees of foaming and also even more than the benefit in weight but still the values seem very reasonable and the parts are stronger than they feel. I have printed half of a wing of the Messerschmitt BF 109 from 3DLabPrint that turned out great and also gluing was no problem at all. It’s of course not as stiff as the wing out of normal PLA but since a whole plane will be lighter with that material, also loads would be lower. The surface almost feels like canvas with the matt, foamed up material. I didn’t finish the whole one yet, but I’ve seen others flying one printed in LW-PLA without an issue. The guys from Eclipson (https://www.eclipson-airplanes.com/)even specially designed one of their 3D printed planes for that material and solved the problem of the lower stiffness and strength by adding carbon fiber rods at critical locations resulting in a model that is light weight and easy to print with the design flexibility of 3D printing. Very cool and if you’re interested in RC airplanes, definitely check them out! You can also, to some degree, dynamically vary the temperature during printing and for example create sandwich structures like this. Changing temperature within one layer will be tricky due to the thermal capacity of your hotend, but what I’d really like to do, is print that material on a multi nozzle printer and for example print the hull of a wing with the LW-PLA and the internal structure with regular material. But in the end, what do you think of this material? Is it revolutionary and what applications do you see for it or do you think it’s obsolete? Let us know down in the comments!

Sandwich Structure printed in LW-PLA